Anhui Safety Medical Devices Co.,Ltd

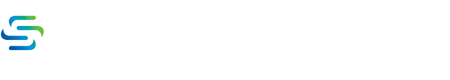

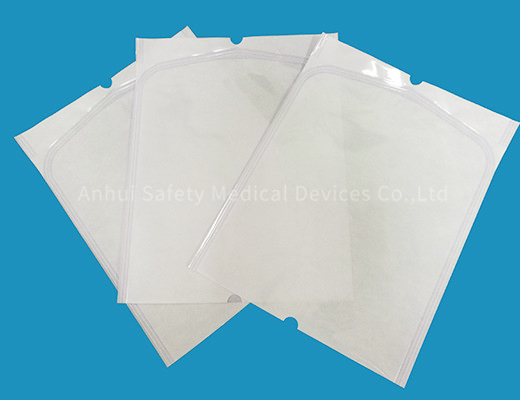

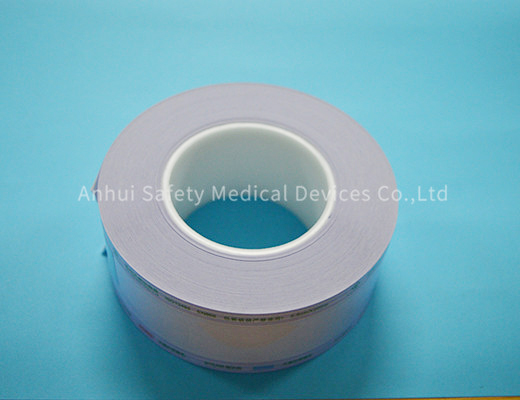

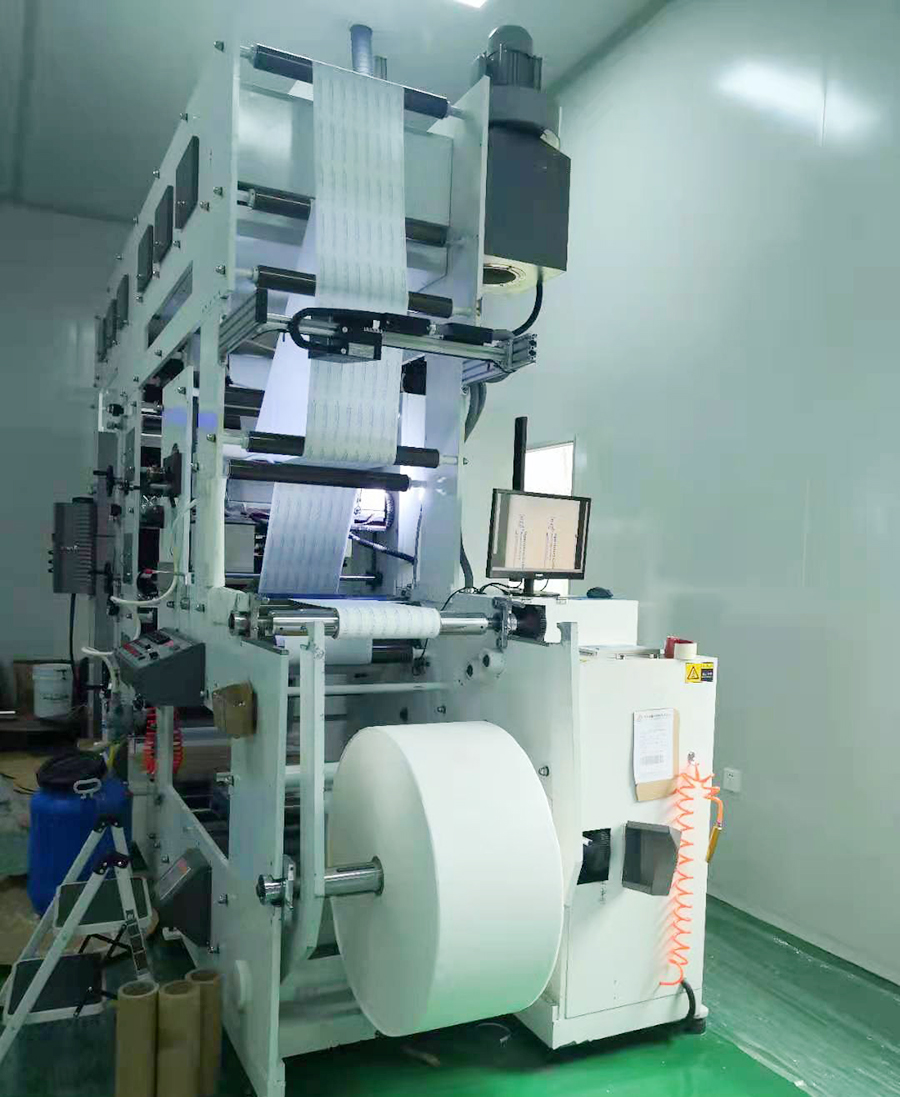

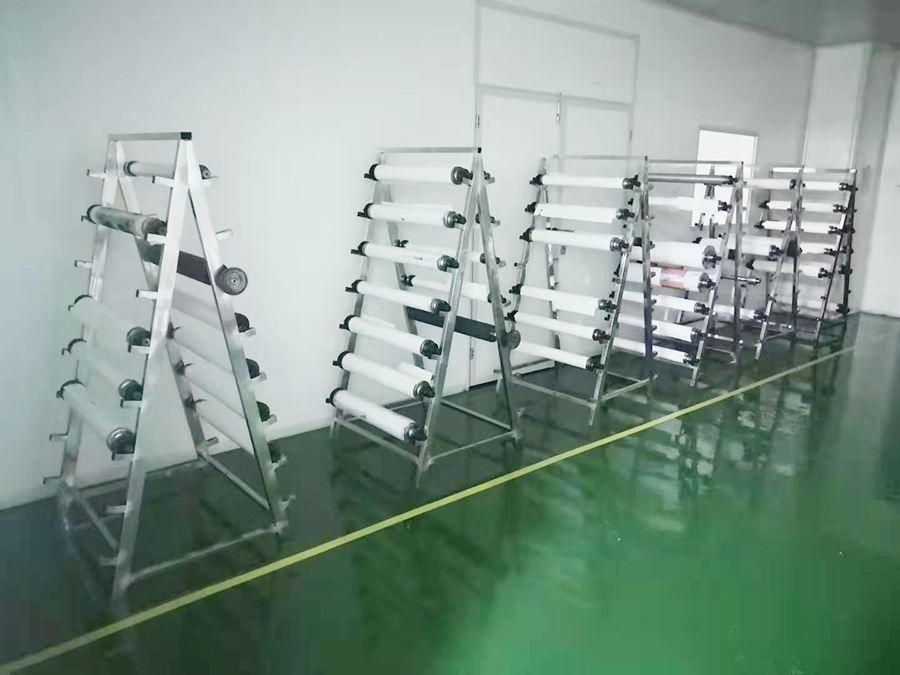

Anhui Safety Medical Devices Co.,Ltd is a domestic research and development, production, sales, service as one of the new medical equipment sterilization packaging company. The company has perfect production technology, complete equipment, with 100,000 class dust-free purification workshop, and passed the ISO13485:2016 international quality system certification, CE and other quality certification. Our products include all kinds of rolled bags and individual bags, including heat sealed flat bag, solid bag, middle sealed bag, top bag, Tyvek series low temperature sterilization bag, etc.

Production and sales services as one focus on medical equipment sterilization packaging

All kinds of rolled bags and individual single bags, including heat sealed flat bag, three-dimensional bag, middle sealed bag, top bag, Tyvek series low temperature sterilization bag, etc

- Phone:0550-2383022 0550-2383033

- Mobile:

- Email:info@safetyah.com

- Address:Qiaotian Road,Tongcheng Town,Tianchang City,Anhui prov.China